- 715 Corporate Center Ct Suite A, Westminster, MD 21157

- help@compressormaintenance.com

- 410-876-5141

- Available 24/7 for Emergencies

Blue aluminum piping is lightweight, durable, and resistant to corrosion, making it an excellent choice for compressed air systems. It ensures a smooth, leak-free airflow and maintains air quality by preventing rust and scale buildup, unlike traditional steel or iron pipes.

Yes, aluminum piping is designed to handle high-pressure air systems, offering excellent strength and reliability. Most systems support pressure ratings that meet or exceed industrial requirements, making them suitable for a wide range of applications.

Blue aluminum piping is easy to install due to its lightweight design and modular system. It typically features push-to-connect fittings, reducing installation time and costs. Its flexibility allows for easy modifications or expansions to the system as needed.

This blower offers vacuum or pressure configurations. A PC based control center simplifies operation. This system featured mechanical seals. Special coatings available include electro-less nickel and Teflon. The magnetic drives were selected to enhance leak tightness between the motor and pump housing. Specialized instrumentation, an explosion proof motor, and high temperature bearings round out the features.

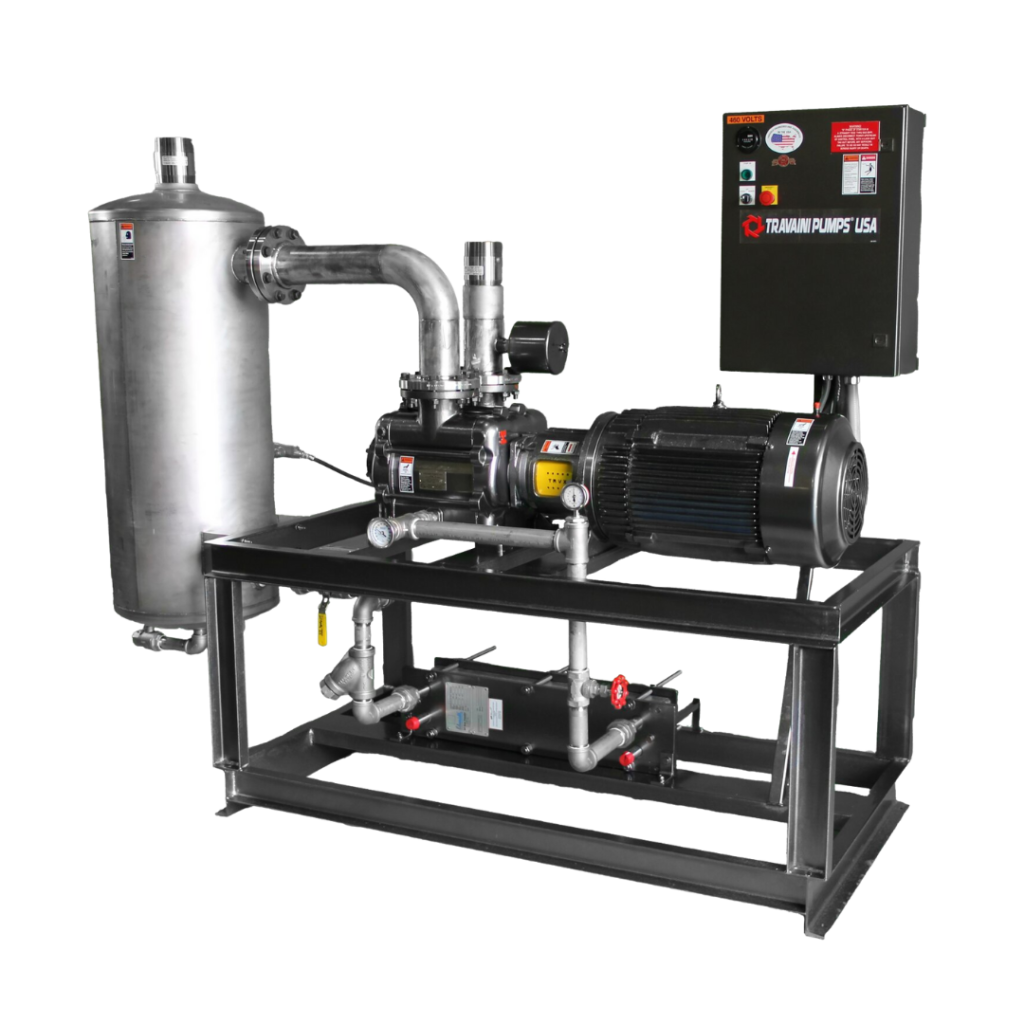

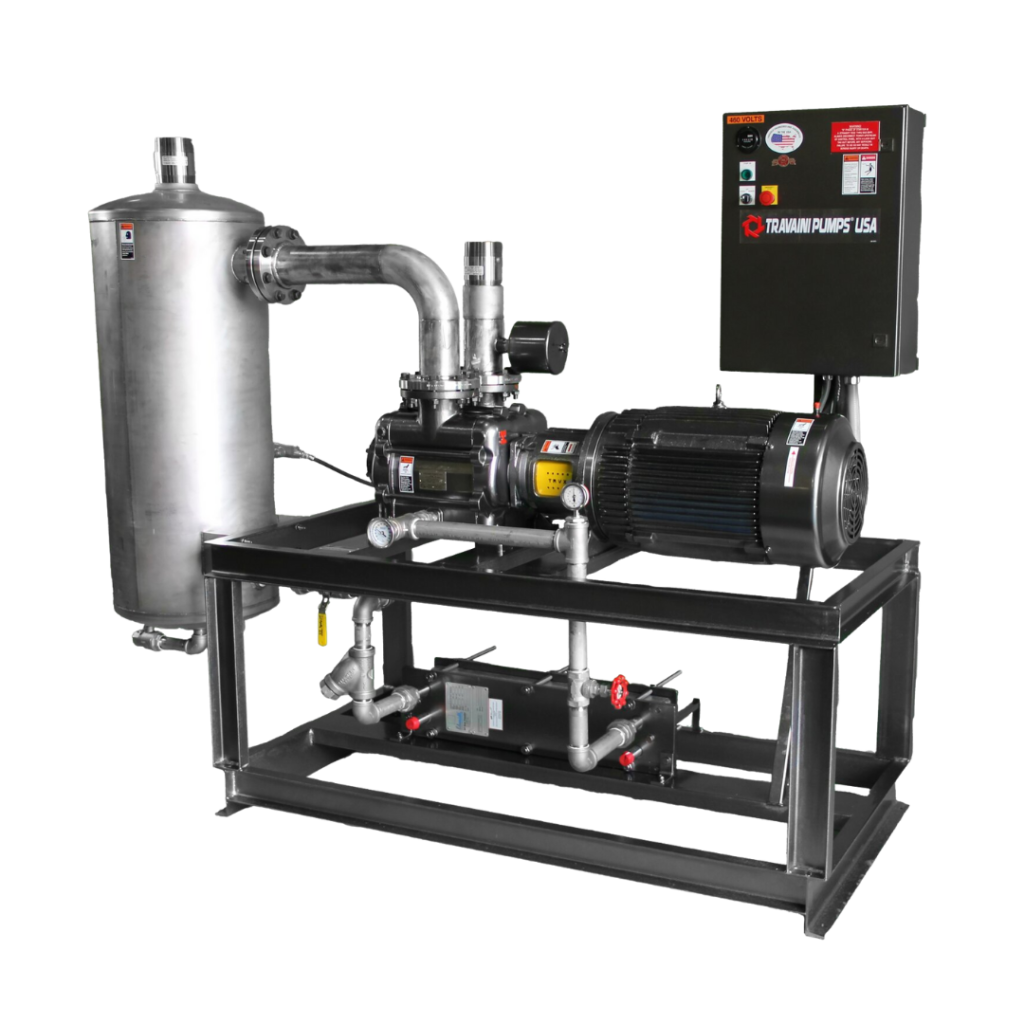

Travaini vacuum pumps and systems are renowned for their reliability, efficiency, and innovative design, making them a trusted solution for diverse industrial applications. With a focus on energy efficiency and durability, Travaini offers a wide range of vacuum solutions, including liquid ring, rotary vane, and dry vacuum pumps, as well as complete vacuum systems tailored to meet specific needs. Whether for chemical processing, food production, or medical applications, Travaini delivers advanced technology to optimize performance and ensure long-lasting operation.

Oil sealed air-cooled liquid ring vacuum systems.

Water sealed water cooled liquid ring vacuum systems.

Oil sealed air-cooled liquid ring vacuum systems.

All systems are designed and built with each customer’s specific needs in mind. Multiplex systems provide an economical advantage by having smaller pumps with lower horsepower operating in a lead-lag sequence. Only the capacity needed at a particular time will be in operation. A “built-in back-up” is provided as a safety net in case one pump requires service.

Suiteable for a wide range of industries:

The non-contact, dry rotary claw design offers a vacuum system for surgical, waste anesthetic gas disposal (WAGD), laboratory and industrial applications. The illustrated systems comes complete with a touch screen control panel, variable speed drives to economically control the speed of the pumps and lower energy consumption, and a fully automated PC controller that can be interfaced with the Building Automation Systems (BAS).

The 3AL is a wonderful alternative to oil flooded pumps that require maintenance scheduling, dry vane pumps that cannot handle water vapor or carryover, or non-contact pumps that must be protected from particulates. All 3AL systems are designed in Simplex to Multiplex configurations and can either be tank mounted or stack/base mounted as shown here.

Single stage oil flooded vacuum systems have been a staple in many of the above mentioned applications and industries for over 50 years. These systems are designed in various configurations to save space – Vertical or Horizontal Tank Mounted or Expandable – Stacked or Base Mounted. Years and years of reliability make these systems a wise choice with only minimal maintenance necessary.

This product utilizes well-known, reliable regenerative blower technology. With no contacting parts and no need for oil or water, it’s a maintenance free design. It features a built-in wash down system. Quiet and reliable, this system allows the dentist to focus on his patients. Simplex to multiplex configurations are available. A special nickel coating is also available to protect against oxidation.

Travaini vacuum pumps and systems are renowned for their reliability, efficiency, and innovative design, making them a trusted solution for diverse industrial applications. With a focus on energy efficiency and durability, Travaini offers a wide range of vacuum solutions, including liquid ring, rotary vane, and dry vacuum pumps, as well as complete vacuum systems tailored to meet specific needs. Whether for chemical processing, food production, or medical applications, Travaini delivers advanced technology to optimize performance and ensure long-lasting operation.

Oil sealed air-cooled liquid ring vacuum systems.

Water sealed water cooled liquid ring vacuum systems.

Oil sealed air-cooled liquid ring vacuum systems.

All systems are designed and built with each customer’s specific needs in mind. Multiplex systems provide an economical advantage by having smaller pumps with lower horsepower operating in a lead-lag sequence. Only the capacity needed at a particular time will be in operation. A “built-in back-up” is provided as a safety net in case one pump requires service.

Suiteable for a wide range of industries:

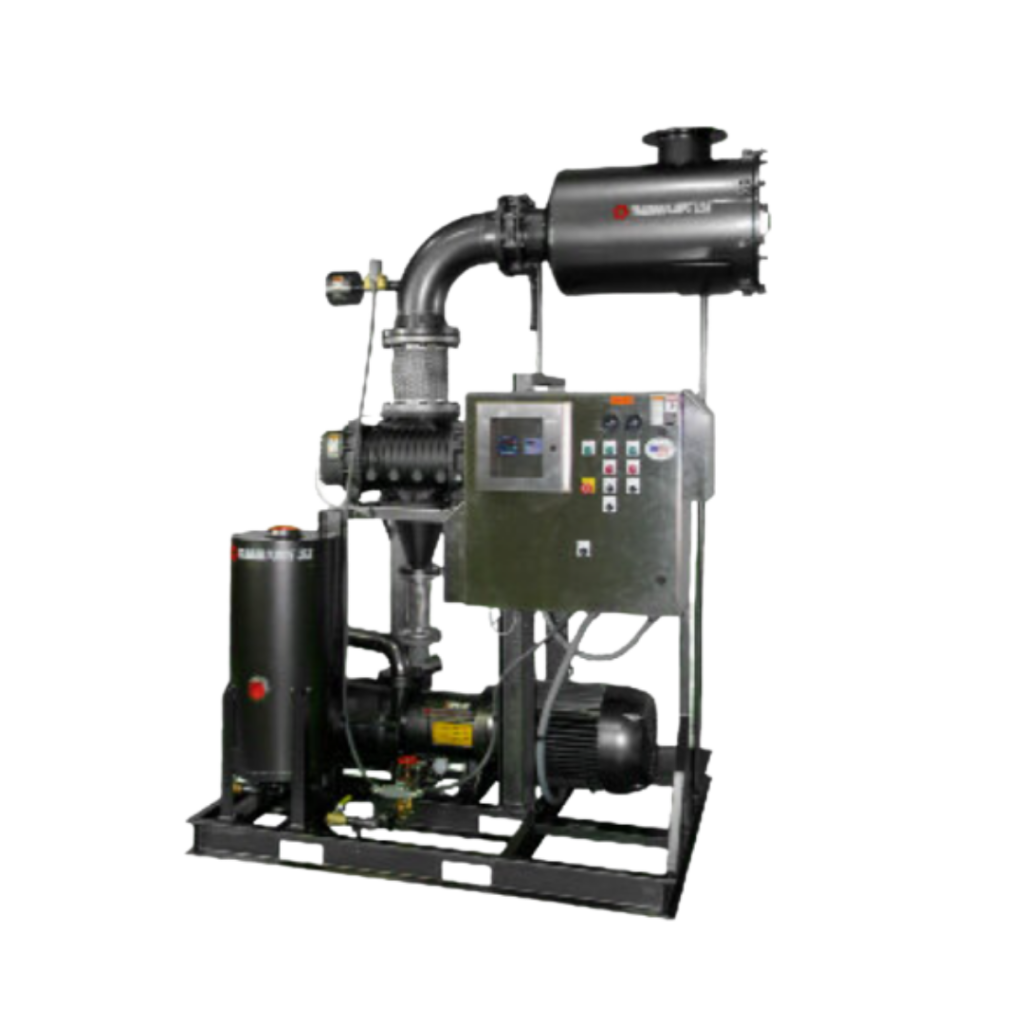

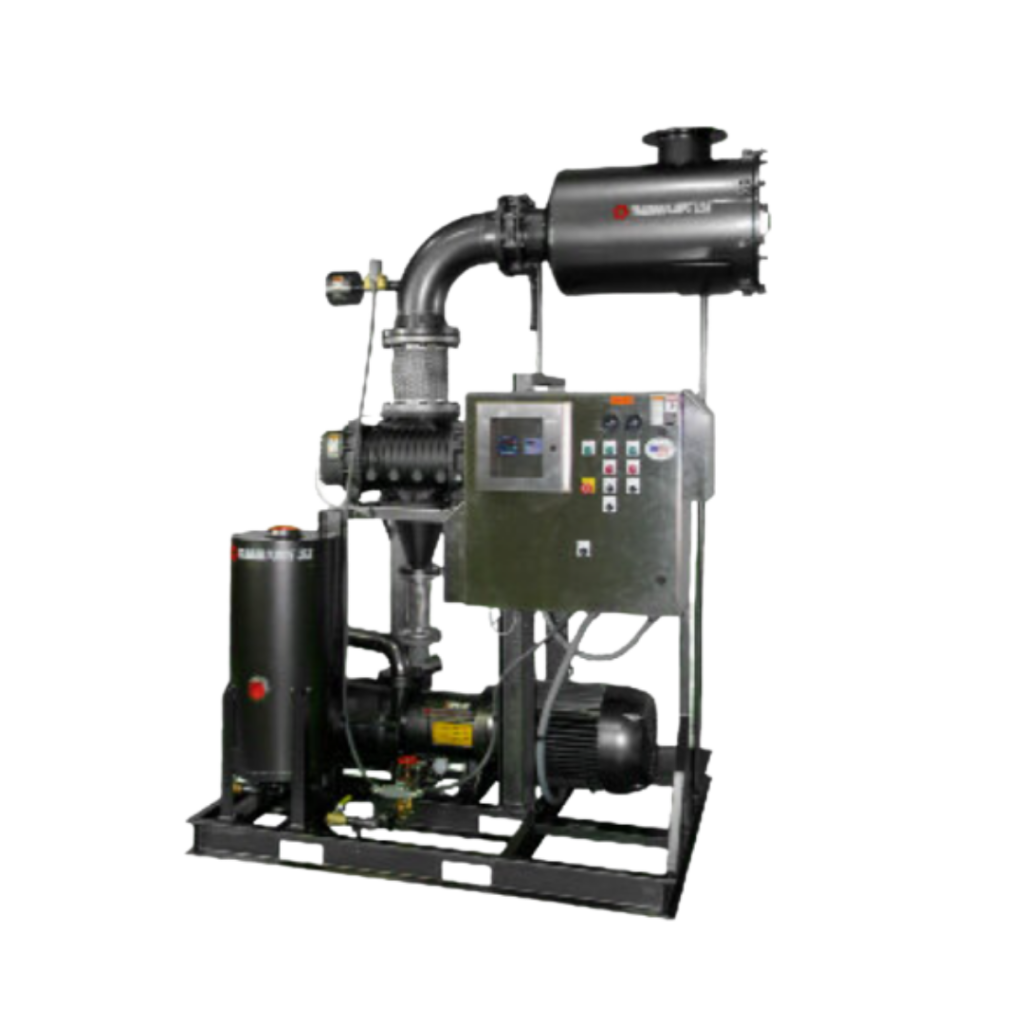

The non-contact, dry rotary claw design offers a vacuum system for surgical, waste anesthetic gas disposal (WAGD), laboratory and industrial applications. The illustrated systems comes complete with a touch screen control panel, variable speed drives to economically control the speed of the pumps and lower energy consumption, and a fully automated PC controller that can be interfaced with the Building Automation Systems (BAS).

The 3AL is a wonderful alternative to oil flooded pumps that require maintenance scheduling, dry vane pumps that cannot handle water vapor or carryover, or non-contact pumps that must be protected from particulates. All 3AL systems are designed in Simplex to Multiplex configurations and can either be tank mounted or stack/base mounted as shown here.

Single stage oil flooded vacuum systems have been a staple in many of the above mentioned applications and industries for over 50 years. These systems are designed in various configurations to save space – Vertical or Horizontal Tank Mounted or Expandable – Stacked or Base Mounted. Years and years of reliability make these systems a wise choice with only minimal maintenance necessary.

This product utilizes well-known, reliable regenerative blower technology. With no contacting parts and no need for oil or water, it’s a maintenance free design. It features a built-in wash down system. Quiet and reliable, this system allows the dentist to focus on his patients. Simplex to multiplex configurations are available. A special nickel coating is also available to protect against oxidation.

This blower offers vacuum or pressure configurations. A PC based control center simplifies operation. This system featured mechanical seals. Special coatings available include electro-less nickel and Teflon. The magnetic drives were selected to enhance leak tightness between the motor and pump housing. Specialized instrumentation, an explosion proof motor, and high temperature bearings round out the features.

Blue aluminum piping is lightweight, durable, and resistant to corrosion, making it an excellent choice for compressed air systems. It ensures a smooth, leak-free airflow and maintains air quality by preventing rust and scale buildup, unlike traditional steel or iron pipes.

Yes, aluminum piping is designed to handle high-pressure air systems, offering excellent strength and reliability. Most systems support pressure ratings that meet or exceed industrial requirements, making them suitable for a wide range of applications.

Blue aluminum piping is easy to install due to its lightweight design and modular system. It typically features push-to-connect fittings, reducing installation time and costs. Its flexibility allows for easy modifications or expansions to the system as needed.

Enough about us, let’s talk about you. Tell us about your project needs.