- 715 Corporate Center Ct Suite A, Westminster, MD 21157

- help@compressormaintenance.com

- 410-876-5141

- Available 24/7 for Emergencies

Industries like food and beverage, pharmaceuticals, healthcare, and electronics benefit from oil-free compressors due to their need for clean, contaminant-free air.

Oil-free compressors eliminate the need for oil lubrication in the compression process, reducing maintenance and contamination risks while ensuring cleaner air.

Yes, many oil-free compressors, such as rotary screw and scroll models, are designed for energy efficiency, helping to reduce operational costs over time.

Oil-free compressors generally require less maintenance since they avoid the need for regular oil changes and filtration, though routine checks are still necessary for optimal performance.

The new LPT 150 low-pressure turbo compressor delivers oil-free Class-0 compressed air at 2-4 bar psi with low operating costs and minimal maintenance. Its optimized, wear-free design offers 30% cost savings compared to oil-free screw compressors, ideal efficiency for low-pressure applications, and quiet operation at just 63 dB(A).

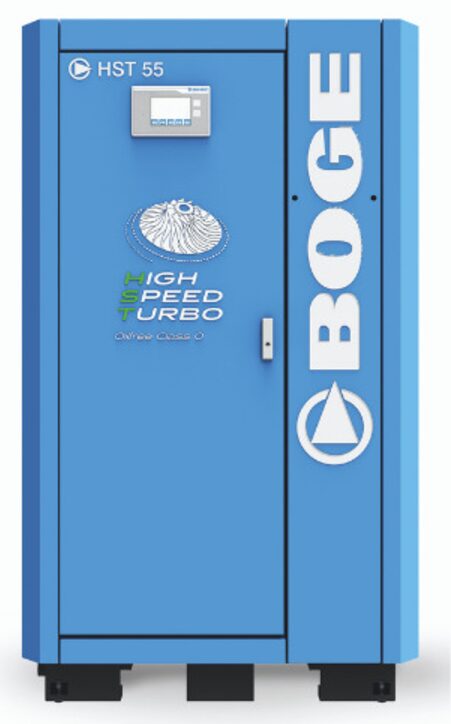

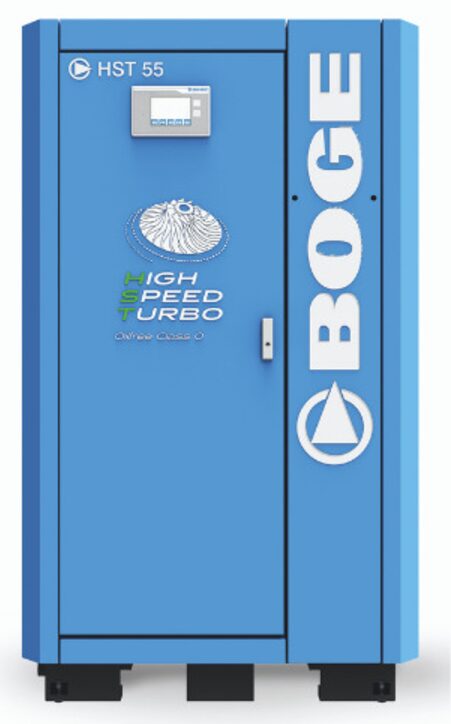

Oil-free rotary screw compressors from trusted brands like ELGi and BOGE provide clean, consistent, and high-quality air for critical applications in industries such as food and beverage, pharmaceuticals, and electronics. With advanced rotary technology, these compressors deliver reliable performance and energy efficiency without the need for oil lubrication, making them ideal for continuous, contamination-free operations.

Oil-free reciprocating compressors from renowned manufacturers like Anest Iwata, BOGE, and Champion are designed for industries requiring clean air with zero contamination risk, such as healthcare, automotive, and laboratories. These piston-driven compressors provide high-pressure air while ensuring zero oil carryover, making them an excellent choice for specialized and intermittent air needs.

Oil-free scroll and turbo compressors from leading brands like Anest Iwata and BOGE deliver high-capacity, energy-efficient air for precision-driven processes in electronics, chemical manufacturing, and medical facilities. These advanced compressors ensure consistent, oil-free air for critical applications, meeting strict air purity standards.

Oil-free rotary screw compressors from trusted brands like ELGi and BOGE provide clean, consistent, and high-quality air for critical applications in industries such as food and beverage, pharmaceuticals, and electronics. With advanced rotary technology, these compressors deliver reliable performance and energy efficiency without the need for oil lubrication, making them ideal for continuous, contamination-free operations.

Oil-free reciprocating compressors from renowned manufacturers like Anest Iwata, BOGE, and Champion are designed for industries requiring clean air with zero contamination risk, such as healthcare, automotive, and laboratories. These piston-driven compressors provide high-pressure air while ensuring zero oil carryover, making them an excellent choice for specialized and intermittent air needs.

Oil-free scroll and turbo compressors from leading brands like Anest Iwata and BOGE deliver high-capacity, energy-efficient air for precision-driven processes in electronics, chemical manufacturing, and medical facilities. These advanced compressors ensure consistent, oil-free air for critical applications, meeting strict air purity standards.

The new LPT 150 low-pressure turbo compressor delivers oil-free Class-0 compressed air at 2-4 bar psi with low operating costs and minimal maintenance. Its optimized, wear-free design offers 30% cost savings compared to oil-free screw compressors, ideal efficiency for low-pressure applications, and quiet operation at just 63 dB(A).

Industries like food and beverage, pharmaceuticals, healthcare, and electronics benefit from oil-free compressors due to their need for clean, contaminant-free air.

Oil-free compressors eliminate the need for oil lubrication in the compression process, reducing maintenance and contamination risks while ensuring cleaner air.

Yes, many oil-free compressors, such as rotary screw and scroll models, are designed for energy efficiency, helping to reduce operational costs over time.

Oil-free compressors generally require less maintenance since they avoid the need for regular oil changes and filtration, though routine checks are still necessary for optimal performance.

Enough about us, let’s talk about you. Tell us about your project needs.